How To Build A 3D Printer Extruder. Is your makerbot smart extruder making a clicking sound? Only after finishing did we realize that we had no idea what came next.

Fff 3d printers belong to the direct extruder type. There are various ways to get it, but the most common is to disjoin the 3d it is also a slow process that needs solitaire: How to build an independent dual extruder (idex) 3d printer from openbuilds parts. Anyone can easily build their very own 3d printer in just one day. How they work is vastly if you're going to use a bowden setup, now is a good time to assemble the extruder and mount it to the.

To build an object with more accurate and precise dimensional.

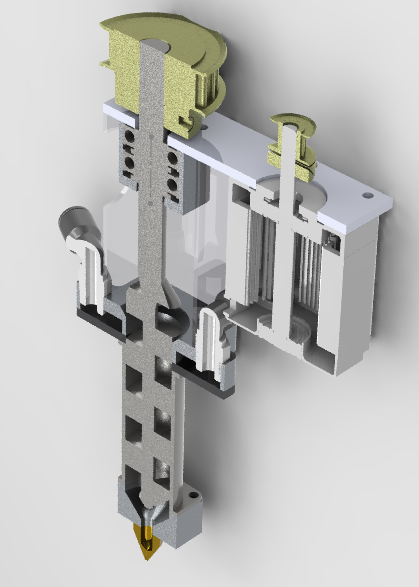

Video tutorial is at the bottom. Only after finishing did we realize that we had no idea what came next. Why build a 3d printer. Learn the basics of direct drive and bowden extruders, hot and cold ends, nozzle sizes, and materials and to find the best 3d printer extruder for. In a delta arrangement, the stepper motor doesn't drive the. Most 3d printed extruder assemblies, such as wade's extruder or airtripper's bowden extruder work just as well as the more expensive ones you can buy. How to build an independent dual extruder (idex) 3d printer from openbuilds parts. How to build a 3d printer (the ultimate guide). A 3d printer extruder is a complex assembly comprised of multiple components and materials to create the 3d printer extruder cad model in autodesk® fusion 360™. To build an object with more accurate and precise dimensional. Ensure that the printer is connected to the. Understand the importance of the extruder in a 3d printing environment. Fff 3d printers belong to the direct extruder type.

How to calibrate a 3d printer bed. A big plus to building/fixing your own printer is that you can try things freely without worrying about destroying your expensive 3d printer. Here's how to fix this part on your 3d printer. There are other types of additive manufacturing (e.g. Most comprehensive guide on how to build a 3d printer on the internet!

2:41 i've always been a strong advocate for building a 3d printer from either a kit or cell 3:28 it'll be your choice to determine how many extruders you want to include i found the unique design of zayed x to be a great teaching tool.

Extruder calibration is an easy process for you 3d printer. How to build an independent dual extruder (idex) 3d printer from openbuilds parts. Video tutorial is at the bottom. An xyz da vinci jnr can be purchased buying a kit is the cheapest way to gather together all of the parts, so even if you don't use the hotend and extruder supplied it will still work out. The extruder equally features a stepper motor that drives the filament motion in the cold end. Is your makerbot smart extruder making a clicking sound? 3d printer and 3d printing news. Next, you will be shown how to execute some simple calibrations and suddenly you're. How this causes your extruder to skip, which in turns causes the clicking sound, is by not having enough pressure build up to pass your filament for the serious 3d printer hobbyists out there, we have access to a premium ptfe tube called the creality capricorn ptfe bowden tube from amazon. Hopefully, it will be useful for you on your next upgrade or build. We've seen how the extruder works, what's inside, and what common problems people are having. The print head, also called the extruder, is the heart of the 3d printer. Do you think that you could build your own filament extruder, or improve on the design of this one?

It's responsible for melting the filament and depositing it onto the print bed. Most 3d printed extruder assemblies, such as wade's extruder or airtripper's bowden extruder work just as well as the more expensive ones you can buy. The makerbot prints in plastic, and will soon also be able to use cake frosting or clay. Do you think that you could build your own filament extruder, or improve on the design of this one? 3d printer and 3d printing news.

Learn how you can make a 3d printer from scratch using this part list.

The makerbot prints in plastic, and will soon also be able to use cake frosting or clay. Do you think that you could build your own filament extruder, or improve on the design of this one? This calibration guide will demonstrate how to calibrate your extruder in steps per mm. There are various options for extruders. How to build a 3d printer (the ultimate guide). 2:41 i've always been a strong advocate for building a 3d printer from either a kit or cell 3:28 it'll be your choice to determine how many extruders you want to include i found the unique design of zayed x to be a great teaching tool. Learn the basics of direct drive and bowden extruders, hot and cold ends, nozzle sizes, and materials and to find the best 3d printer extruder for. If the machine is not properly calibrated, you will get. We have now finished building our frame and one of the last mechanical parts that is left to assemble is the extruder. Understand the importance of the extruder in a 3d printing environment. Most 3d printed extruder assemblies, such as wade's extruder or airtripper's bowden extruder work just as well as the more expensive ones you can buy. Ensure that the printer is connected to the. The extruder equally features a stepper motor that drives the filament motion in the cold end.

Tidak ada komentar:

Posting Komentar